Improved visibility, efficiency and reduced cost; Just 3 of the benefits transport and logistics can realise from Cross Docking

What is cross docking?

Efficiency and speed are crucial in the haulage industry, particularly with pallet operators. Companies are constantly looking for ways to reduce costs, improve delivery times, and streamline operations. One method that has gained significant attention in recent years is cross docking. But what exactly is cross docking, and how can it positively impact haulage operations?

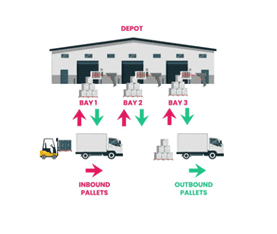

Cross docking is a method in haulage where palletised goods are taken from one point to another, and dropped off at a place inbetween for re-routing to a destination. Goods are directly transferred to outbound transportation without being stored in a warehouse, and instead held at a transit shed until it’s time for the goods to be delivered (often with a quick turnaround). This would be made up of multiple vehicles as part of the same job, with Vehicle A handling the inbound drop off to the transit shed and Vehicle B picking it up and delivering the palletised goods to the destination.

This method is different to traditional warehousing, where goods are stored for extended periods before being dispatched to customers. Instead, cross docking reduces the need for warehousing and inventory management, cutting costs and saving time.

The Cross docking process

The cross docking process is generally handled in the following steps:

- Inbound shipment: Products arrive at the cross docking facility (transit shed).

- Sorting and consolidation: Upon arrival, palletised goods are unloaded and scanned off a vehicle and placed in a temporary location. Technology can inform staff where the palletised goods should be placed along with other goods going to the same or similar locations.

- Outbound shipment: Once sorted, the palletised goods are then loaded onto outbound vehicles which will then deliver them to their destination such as the customer or retailer.

Benefits of cross docking in haulage

Cross docking offers several significant advantages to haulage companies which is why more and more companies are choosing to use cross docking over warehousing:

- Reduced storage costs: As products don’t sit in a warehouse for long periods of time, hauliers can eliminate the cost of inventory storage, leading to lower operational costs.

- Faster delivery times: Cross docking allows for the quick transfer of goods from inbound to outbound vehicles, saving time. This is highly beneficial for businesses that need fast delivery, like those in e-commerce.

- Improved efficiency: Cross docking transit sheds are designed to facilitate quick movement of goods, which improves overall efficiency.

- Reduced risk of damaged goods: As goods are only held in the transit sheds briefly and not stored in the warehouse for a long time the risk of damaged goods is lowered.

- Greater visibility: Operators have visibility of pallets arriving, which can then be scanned and moved to the right location and loaded to the right truck at the right time. It also enables hauliers to keep track of the last known location of the goods, minimising time wasted trying to find goods that have gone astray.

- Increased load-fill: As operators can see pallets arriving, they can plan ahead, ensuring trucks are full when they leave, therefore optimising the use of their vehicles.

Downsides to Cross docking

While cross docking offers several benefits, there are of course some negatives. These include:

- High initial investment costs: Setting up a transit shed can be costly. Companies will first need to invest in the cross docking infrastructure, such as docking bays, sorting equipment, and efficient software to aid the cross docking process.

- Complex coordination: Coordinating the inbound and outbound shipments and ensuring that the right goods are sorted and sent to the right destinations can be complex, requiring the previously mentioned software.

- Not suitable for all goods: Cross docking works best for goods that are in high demand and need to be transported and delivered quickly.

Cross docking is a method that is growing in popularity with hauliers as it provides hauliers with faster, more efficient ways to move goods. While the practice requires careful planning and investment, its benefits—such as reduced storage costs, faster deliveries, and improved efficiency and visibility—make it a great option for road transport and logistics companies looking to maximise the efficiency of their operations. Based on current trends and the needs to keep costs to a minimum in the haulage industry the cross docking practice will only continue to grow.

If you are interested in adding cross docking to your business please visit our cross docking app webpage for further information.